Comprehensive Cane Sugar Processing Chemicals: Throughout

Comprehensive Cane Sugar Processing Chemicals: Throughout

Blog Article

Unleash the Possible of Your Workflow With Proven Walking Stick Sugar Processing Chemical Formulas

In the world of cane sugar processing, the mission for functional excellence is a continuous pursuit - Cane Sugar Processing Chemicals. The use of proven chemical formulations has actually emerged as a vital element in enhancing production processes and boosting general efficiency. By integrating these solutions right into your procedures, a spectrum of advantages waits for, promising enhanced returns, increased purity degrees, and structured procedures that straighten with your tactical objectives. As the industry advances, staying abreast of these innovations could be the setting apart variable that propels your procedures to brand-new heights of success.

Enhancing Manufacturing Performance

To maximize manufacturing effectiveness in walking stick sugar handling, it is essential to enhance operational processes and take on cutting-edge modern technologies where appropriate. By executing effective operational procedures, such as automating manual jobs and making use of data-driven understandings, sugar processing plants can considerably enhance their performance levels.

In addition, incorporating state-of-the-art modern technologies like expert system and device discovering can even more revolutionize the walking stick sugar processing market. These technologies can examine huge quantities of data to optimize process criteria, anticipate devices upkeep needs, and enhance general plant performance. By accepting automation and digitalization, sugar processing facilities can operate with higher accuracy and dependability, eventually leading to increased manufacturing output and improved item quality. Basically, the quest of production effectiveness with structured procedures and cutting-edge technologies is critical for the sustainable development and competitiveness of walking cane sugar processing procedures.

Optimizing Returns and Purity

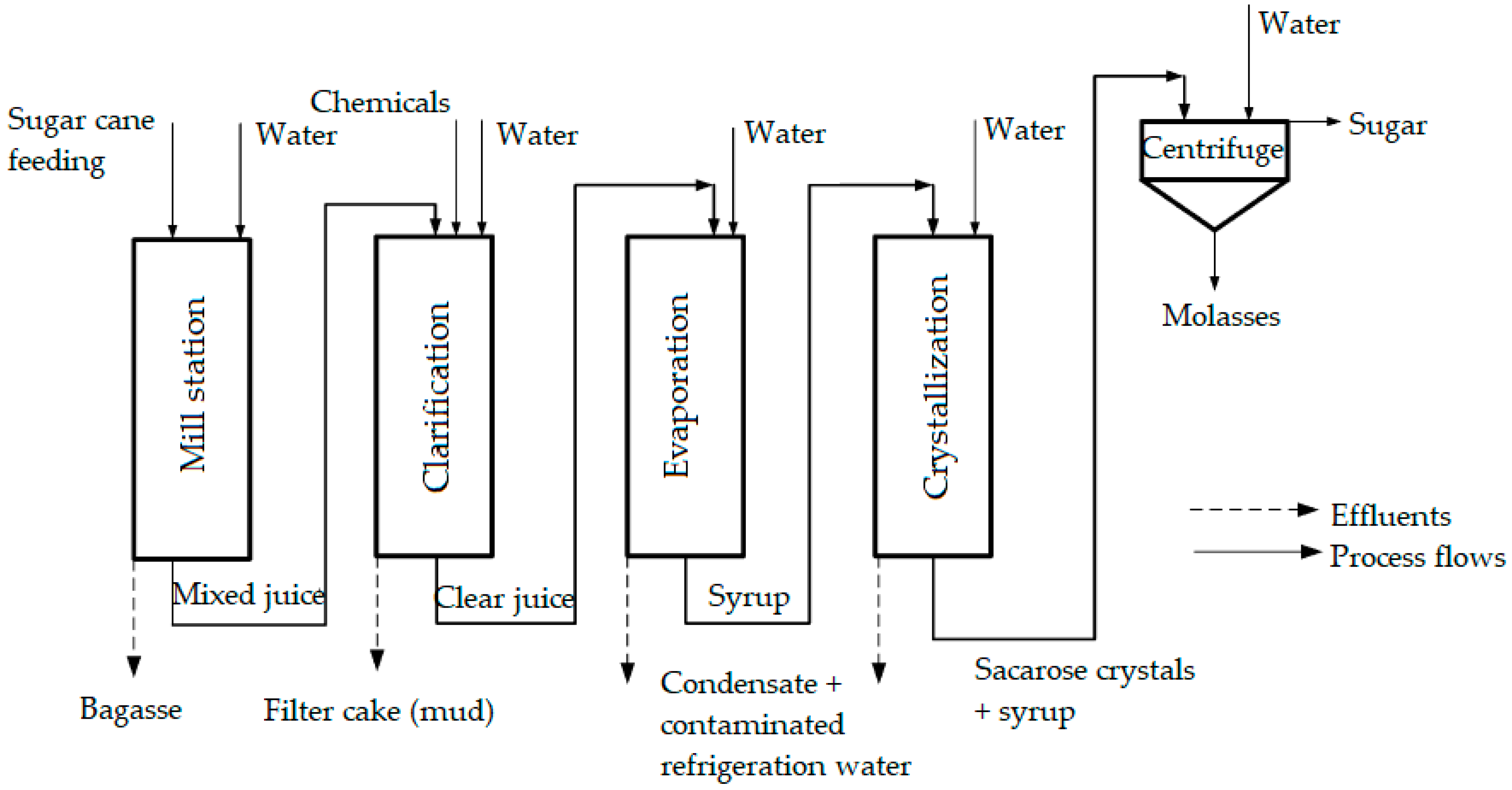

Efficiently making the most of yields and preserving high pureness levels are crucial goals in the walking stick sugar handling market. Accomplishing ideal returns while maintaining strict purity requirements calls for a calculated method that incorporates innovative chemical solutions right into the handling workflow. By using customized chemicals made to enhance extraction performance, clear up the juice, and boost formation processes, sugar mills can significantly improve their general yields and pureness levels.

Improving Process Optimization

In the world of walking cane sugar processing, enhancing process optimization is critical for accomplishing the desired yields and purity degrees while integrating advanced chemical solutions for boosted performance. Routine maintenance schedules and comprehensive cleansing treatments also play a critical role in keeping the handling plant running smoothly and stopping unexpected downtime. Welcoming process optimization as a core principle can lead browse this site to lasting enhancements in efficiency and item top quality within the cane sugar handling market.

Getting Operational Goals Efficiently

With a calculated emphasis on functional excellence, the sugar processing industry intends to effectively satisfy its production targets and top quality standards. Achieving functional objectives successfully calls for a mix of variables such as structured procedures, advanced innovations, and maximized chemical formulations. By guaranteeing that each step of the sugar processing procedure is carefully prepared and performed, companies can enhance effectiveness and efficiency.

One key facet of attaining operational goals is the the original source selection of premium walking cane sugar handling chemical solutions. These formulations play a vital role in various stages of the production process, consisting of removal, purification, and condensation. By utilizing proven chemical formulations specifically made for cane sugar handling, firms can improve return, lower processing time, and enhance the total quality of the end product.

Additionally, reliable interaction and cooperation among different departments within the company are crucial for lining up functional objectives and guaranteeing smooth operations - Cane Sugar Processing Chemicals. Regular performance evaluations, continuous training programs, and data-driven decision-making processes can even more support the achievement of operational quality in the sugar handling industry. By executing these methods, business can unleash the full possibility of their procedures and stay in advance in an affordable market

Enhancing Output High Quality

Additionally, enhancing final result quality likewise requires continual monitoring and modification of processing criteria to maintain uniformity and meet high quality specifications. Quality assurance measures such as regular testing for purity, wetness web content, and granulation make sure that the end item satisfies industry criteria and consumer expectations. By purchasing the best chemical solutions and prioritizing high quality throughout the manufacturing procedure, sugar handling facilities view it can attain superior final product quality that establishes them apart out there.

Final Thought

Finally, utilizing tested cane sugar processing chemical solutions can significantly boost production performance, make best use of returns and pureness, improve procedure optimization, attain operational objectives effectively, and boost final product top quality (Cane Sugar Processing Chemicals). By integrating these formulas right into operations, business can open the complete potential of their sugar processing centers and ensure an extra streamlined and successful production procedure

Report this page